Pictures and text by Bob Roberts

See below for photo gallery.

|

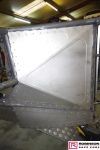

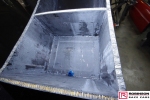

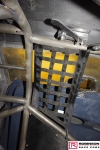

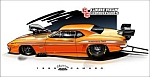

Bob Roberts has kindly sent a gallery of pictures taken by him whilst the build of Eurodragster.com sponsor Andy Robinson's Pro Modified Anger Management '69 Camaro took place at Robinson Race Cars. The car was the first British Pro Mod to run in the five second zone, competing successfully for six years including four championships until it was destroyed in a top-crash at the 2018 National Finals, fortunately with no injury to Andy. The story starts in mid-2011 when Andy ordered a 1969 Camaro body in carbon fibre from Cynergy, one of the first from a new mould they had developed. It duly arrived in time for Christmas of that year. Work did not really start until early 2012 and progressed at reasonable speed to meet the desired debut at Easter 2013. The intent was to build in as much lightness as possible which was demonstrated when the Camaro tipped the scales at 200 lbs less than the predecessor Studebaker. In part this was achieved by using more exotic materials and in part by using less of conventional materials where permitted by the regulations. Probably the most significant design change was the use of a carbon composite spine to support the rear of the car. Based on carbon fibre skins with aluminium honeycomb sandwiched between this U-shaped section rested on the rear part of the chassis above the suspension mounts. This also provided a volume to be used for the puke tank. See pics 58, 59, 76 and 98. The structure was designed to accept all the downforce generated at 240 mph. Andy’s short flight at the end of the 2018 season demonstrated an unexpected advantage of the arrangement when the structure received a load from below and collapsed thus reducing the Camaro’s aero profile by 40%. There is no plan to confirm this advantage with the new car. Carbon fibre was used extensively throughout the car to the point where RRC built an oven so more could be done in-house and indeed offered for sale. Wheel tubs, door panels, floor, closing panels at the rear and door bar in fills were all made in-house. See pics 65, 72, 73, 75, 77, 78, 79 and 80. Another route to lightness was the use of titanium most obviously in the firewall but also in the prop shaft tunnel and chute mounts. The challenge of how to attach titanium sheet to chrome moly chassis was solved by TIG brazing some thin sheet steel to the chassis then trimming it to the minimum which allowed for solid rivets to hold the titanium. Pics 54, 55, 84 and 104. The chassis is based on conventional twin rails. Normally there would be vertical tubes between the rails and diagonals between those verticals to give a triangulated structure. In this chassis the diagonals have been replaced shear plates which give added stiffness without a weight penalty. See pic 35. The Camaro was one of the first chassis to feature the RRC developed double adjustable four-link plates which give a very wide range of potential adjustment. Pics 18 and 99. The top mounts for the front struts also feature an RRC special in offering ride height adjustment which is not based on moving the spring mount. Pic 29. Most of the pictures here belong to RRC although I’ve included the Cynergy promotional graphic which is uncannily close to the orange version of the car, a shot by Julian Hunt showing Andy trying to remove his own advert from the track (see pic 122) and a top end picture by Matt Woods for no other reason than I like chute shots. |

| Click on any thumbnail for a large image. | ||||

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||