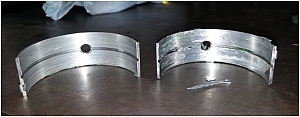

As told to Monday 13th October 2014: Some days it is better to stay in bed. After nearly two years of ‘cackle’ appearances, June 8th 2014 saw the Allard Chrysler Action Group (ACAG) team assemble at Beaulieu for what was planned as a pretty straightforward day preparing the dragster for its appearance at the Beaulieu Hot Rod and Custom Show the following weekend plus a couple of test engine runs. However, it proved to be anything but straightforward and the start of a pretty traumatic period as far as the restoration project was concerned. The first signs that this would not be a normal day were flakes of metal in the sump. After investigation the team checked crank end-float and the mains caps. One of the mains cap appeared to be damaged by metal to metal contact on one side. There was no option but to remove it, only to find further damage to the shells. After a team discussion it was decided to remove the Chrysler Hemi engine for repairs. As regular readers will know this is not easy on the Allard and it took up the complete day. After it had been removed from the chassis it was mounted on its display trolley. The dragster was re-assembled in temporary display condition – sans a few key components like an engine and gearbox. This was how the dragster was when we started the restoration a few years ago. Because the car has a complete body enclosing the mechanicals it still looks good on display in the museum, although it was put together in a bit of a hurry this time and more work would be required to properly secure the headers. Further investigation of the engine revealed more damage and it looked as if the crank had been trying to move towards the front of the engine. Number 5 (the rear bearing) was worn badly; number 4 looked relatively OK; number 3 (centre thrust) was bad; number 2 was not too bad and number 1 was badly worn. The thrust bearing and every main cap side had worn on the rear face with the crankshaft pushing forwards. The front faces of the caps were completely untouched. The main cap 3 had a small chunk missing on the opposite side to the locator tab hole. Why had all this occurred? There were several thoughts. Looking at the bearing wear we wondered if it might be a balance problem. The crank was balanced when the engine was recreated in the USA, but since then a flywheel was added to the rotating assembly. Although they are produced with a neutral balance this might cause a problem if modifications resulted in it being slightly out of balance. With a relatively fast idle (2500 + RPM) it could certainly tear up the main bearings as seen? However, more likely is that the bearings had got washed by fuel in the oil with the extra methanol running time done since Christmas 2013, and not enough regular oil changes. Another chain of thought could support this analysis. We have used the starter motor for turning the engine without a fire-up on many occasions - valve lash, getting fuel from tank to injectors, draining fuel through new blow-off valve manifold drain, checking for oil pressure pre-fire-up, etc. During these starter motor turns we could not get any oil pressure readings on the cockpit gauge after the initial runs two years ago when the oil was fresh and un-contaminated. Could it be that the zero oil pressure reading during these activities was telling us something we didn't give it credit for? Maybe the contaminated oil in the sump had resulted in an oil pick up problem on initial starter motor turn? Up until now our thinking had been that the blower was throwing too much of the fuel to the rear cylinders which run rich compared to the others. This would result in an unbalanced engine with more fuel to get past the rings in the rear cylinders. This works against us running a higher volume of fuel that would enable cooler running. However our thinking was to be proved incorrect as far as which cylinders were running rich, although the view of an unbalanced engine was sound. There were thoughts about using slightly thinner oil. Back in the day it was a common practice to use a "Warm Up" oil and then swap over to full race weight oil once the motor was hot. This would mean that at the start of each run up session the first fire up would be on thinner oil, and then it would need to be swapped for thicker oil because the bearing clearances on the crank have been set for race weight oil and once warm would be too great for a thinner grade. Other options for circumventing the problems regarding obtaining oil pressure on initial start-up would be an external connection into either and oil gallery or the oil pump outlet that would "feed" the system via either a hand pumped or pressurised supply to ensure there was sufficient oil in the system prior to starting. Alternatively, to prime the system prior to firing, the magneto could be removed and an oil pump drive attached to a speed brace inserted and the oil pressure obtained (this is how some of the fuel engine teams do their engines due to oil pick up drain back). This does however mean the mag will need to be re-timed at the start of each session. But using thinner oil needs to be looked into carefully. These old engines have heavy rotating assemblies and benefit from a good cushion of oil. Our thoughts were that we should not go below 20w-50w racing oil that has a higher level of zinc - good for old engines with solid lifter camshafts. Lucas also recommends the use of zinc based grease on the bottom end components. We concluded that it needs to be a case of precautionary oil changes after every cackle session (2 start ups). Then we need to introduce a routine for checking a couple of bearings – probably every six fire-ups. The crank was removed and initially taken to Roland Alsop Engineering. After initial inspection he believed it would be ok with just a polish and turning the crank web to remove the damaged area. Once that was carried out we could order the right size bearings. We would also try and locate some replacement end-caps. In the end he had to take 25 thou off the web. The big concern was the damage to the 3rd main crank web on the rear face. It had grown deeper than a standard thrust bearing width and if left like that would just rip the mains apart again. His thoughts about the cause of the damage were;

As neither of these directly applied to our operation we needed to take these thoughts on board when re-assembling. We had to check whether the blower on the front had too much end float, which in-turn could be grabbing the crank forwards. Likewise did we know if the end float on the gearbox input shaft was correct, as if that is insufficient the crank will be under load and will be pushed forward. We had been running the engine without an effective transmission for some time. In the end Roland Alsop did not feel they could carry out a weld repair so the crank shaft was taken to Fields Engine Service in London www.fieldsengineservicee11.co.uk. The company carries out crank repairs for many drag racers and after inspection they felt it was repairable. It was then ground to standard size. We supplied Federal Mogul bearings so that the machining could be carried out to match the bearing.

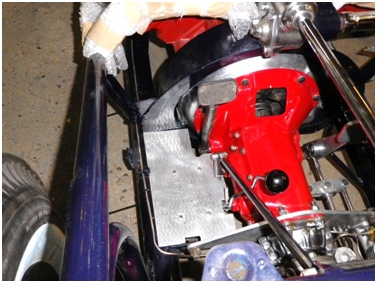

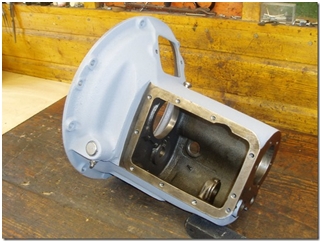

On a different note the cracked gearbox referred to in a previous blog was taken apart and re-assembled in a replacement gearbox casing obtained from the USA. It just required painting red – or so we thought. Unfortunately the box was dropped on the floor and the new casing was badly damaged. For a long time it went very quiet in the workshop as we all came to terms with what this might mean to the project. We needed to order yet another casing from the USA. Although it looked to be a bit heavy for the task in hand the new clutch was checked out for fitment to the flywheel. We had ordered two friction discs. With a slight modification to one friction disc (4 mm taken off the spindle mount to allow contact) and the tapping of a dowel hole to enable a sixth bolt to be put in place, things seemed to be correct. This would need to be balanced with the repaired crank. The engine trolley had been painted black and so the engine with blower could be installed for display at the museum and forthcoming shows. A cardboard tube held the rods in place while the crank was out being repaired. The dragster sans engine, etc., was transported to the Goodwood Festival of Speed and we were pitted next to Rat Trap, one of the two American Fuel Altereds appearing at the Dragstalgia meeting at Santa Pod some two weeks later. Lord March paid us a visit during the show.

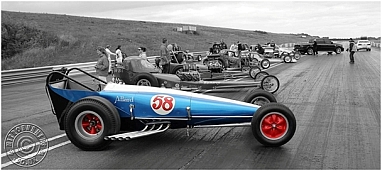

During the weekend July 12/13th the dragster was displayed at the Santa Pod Dragstalgia meet. This is always a good fund raising event – much needed with the repair costs building up. We also picked up a presentation folder of 1963/64 press cuttings and letters from Mooneyes delivered by American racer Dale Snoke. More about this later. Another American racer Julie Braskett posed with the car. She had followed the project via Social Media and, now residing in the UK, wanted to discuss how she could help out. More about this later on as well.

Because the restoration is based on the availability of volunteers and funds available it is not always possible to do all the required work when we would like. So once back at the National Motor Museum, Beaulieu we started to prepare the engine for crank balancing and it was then that more damage was discovered. One piston was very lightly marked but serviceable, three were pretty badly chewed up and 1, 2, 5 and 8 would require replacing and the cylinders honed to remove the marks (hopefully that would be sufficient). Number 8 was only very lightly scuffed. On Number 5 piston the damage had trapped the oil control ring so that would require replacement. Again it was thought that poor lubrication had caused the problem. The camshaft was not inspected at this time. With all this work required it was time to re-think our complete service and repair strategy. The feeling was that we now needed a professional engine builder to re-build the 354 and help sort out our transmission problems. Although we had the expertise within the ‘greater’ ACAG Team they were not always available to us due to their own race team commitments. We had some funds but would need more. Initial publicity about the need for an engine builder brought forth some interesting responses and these were analysed. They included Denny Hummel who originally built the engine when he was a partner in Booth-Arons, but although he offered to do it free of charge (including the parts) the logistics of transferring the engine to and from Detroit needed to be overcome. And it made sense for us to build the expertise in the UK if possible. Denny did however offer to source the parts. Rob Loaring of ICE Automotive also offered to help. Rob’s business partner Nick Davies has been a big supporter of the project. But what about our need for more funds? Our calls for help to cover the extra work soon generated support. American drag racer Julie Braskett confirmed her interest and offered £1000 sponsorship. I handed the money over to Doug Hill, Museum Manager and Lord Montagu’s Chief Engineer, on August 16th.

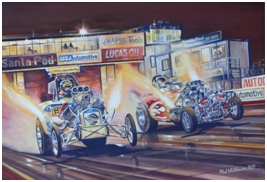

Julie said. “I have been following this project on-line long before I moved to the UK. It is so important to cherish our history and this dragster has a fan base both sides of the Atlantic. Now I have seen the car up close it is even more beautiful than I thought and I’m so pleased to be able to help the team keep it running. I’m looking forward to sitting behind the wheel when it is ready to cackle again”. Nick Davies was the top bidder for the latest original painting donated by Paul Whitehouse. He has quite a collection now. Paul has been a long-time fan of the Allard Chrysler restoration project, donating several original paintings for auction. When he heard that the group needed to obtain additional parts, plus the services of other facilities for the engine rebuild, he was straight on the telephone and donated his fabulous painting of Rat Trap and Pure Hell at Dragstalgia 2014.

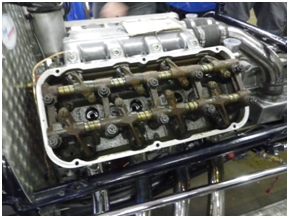

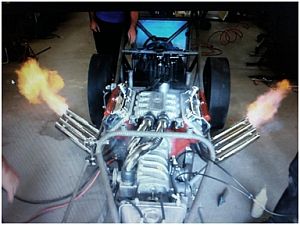

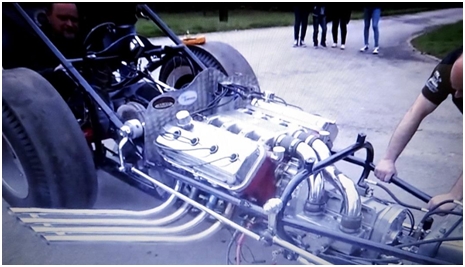

Another donation came in the form of a period crash helmet painted in Allard colours. The helmet was donated by Mark Coulsell but the artwork and paint was applied by Lee Patrick of HRS Designs of Tamworth. This will be displayed with the dragster at the National Motor Museum, Beaulieu along with the starter trolley. This is our second period crash helmet – the first being donated by Cliff and Sharon Watts. Added to the funds raised at Dragstalgia, the financial donations boosted our kitty considerably and we were ready to get the engine back making a noise again. Further help came when Rob Loaring of ICE Automotive confirmed that he would lead our team in the engine rebuild work using his Silverstone workshop. In the meantime the car – sans engine - would remain on display at its home in the National Motor Museum, Beaulieu. So August 15th saw a small team assemble at Beaulieu to prepare the engine for inspection by Rob. It was taken off display and stripped down so that he could inspect the damage in the bores and on the pistons, cams and cam lifters. We learnt that the rear two cylinders had been running lean and not suffering from over-fuelling as had been our thoughts up to now. The main damage was to the front two pistons and bores due to over-fuelling washing past the rings and corrupting the lube system. Still a fuel distribution problem causing oil contamination but not quite the one we had assumed.

Some of the lifters were convex and some concave so it was thought the cam would also be damaged although we didn’t access it at this time. Rob thought that we needed a set of 10 pistons – sizes to be specified once the bores had been finally honed by ICE Automotive. We also needed a cam and lifters and some information about the minimum recommended valve spring pressure that could be used with this set-up. It was further decided that the rebuilt engine should be suitable for running on methanol with nitro running an option rather than the norm. It was something the museum were keen on and more closely represents the way Sydney and his team ran the car back in the 1960s. I know the ‘cackle’ purists will have something to say but balancing the show aspects with the originality of the project is never a smooth ride. We would increase the compression ratio to suit these requirements.

A few days later the team broke down the engine to short block only and transported it to Silverstone so that Rob could hone the cylinders. My job was to contact Denny Hummel to check out availability and lead times on the pistons, cam and lifters along with information about the valve spring pressures. Rob carried out a first stage light honing at ICE Automotive and identified the finished bore size as 4.066". This would enable Denny to re-calculate the piston volume required for our target 10:1 compression that will facilitate our methanol running as the first option strategy. Wayne Brooks at Race Tec confirmed that the piston lead time would be 4-6 weeks. Dave Crower recommended the same cam profile for the replacement cam. Denny also confirmed that a valve spring pressure of 100 pounds at the seat would be about right. The next stage will be for the ACAG team to go to Silverstone and mock up the crank, bell housing and transmission to see what we have. However we would need to re-assemble the replacement gearbox first and Chris Eames re-joined the team to carry out this work. I made copies of the original Booth-Arons ‘Build Book’ for Denny and Rob. More details about the engine problems can be found on our Autumn on-line issue of ACAG Update on drceurope.co.uk/acag/aug2014/

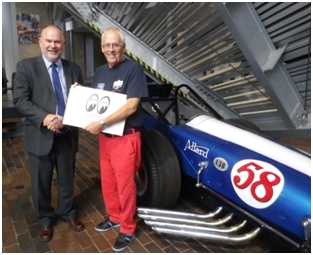

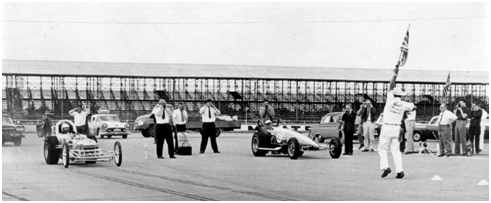

Earlier in this blog I mentioned the Mooneyes Archives presented to us at the Dragstalgia Meeting in July. Most readers will know that Dean Moon was very much involved in supplying parts and advice to Sydney Allard’s team back in the winter of 1960/61 when Europe’s first dragster was being assembled in the Allard Motor Company Clapham workshop under Sydney’s office. Dean was also very much involved in bringing Dante Duce and the Mooneyes dragster across to appear in the UK during 1963. What was not known was the fact that Dean kept copies of the correspondence linked to the 1963 trip in his office drawer, along with press cuttings. They have been discovered only recently and, backed by Shige Suganuma and Chico Kodama of Mooneyes, have been copied and printed in a folder by Allison Jobe of SXS Performance in California. The completed publication has been donated to the National Motor Museum, Beaulieu as part of the archives linked to the Allard Chrysler dragster. Along with lots more information it can now be accessed by researchers using the library at the museum. I re-presented them to Russell Bowman, CEO National Motor Museum, Beaulieu. Russell said, “Our heartfelt thanks go out to all those involved in preserving this piece of history. The National Motor Museum, Beaulieu is proud to include it in our archives. Preserving the documents linked to our exhibits is a vital part of what we do and this document includes a considerable amount of previously unknown information about Sydney and his drag racing activities”.

A new book by Doug Boyce has just been published reviewing some of the most influential cars in the world of drag racing. As Europe’s first dragster, the Allard Chrysler is one of the featured cars. We are in fantastic company and I would like to thank Doug for including us. This link takes you to more details. BDRHoF work My other role with the British Drag Racing Hall of Fame Management Group has been taking up a lot of time. We have been very busy as the date approaches for the most ambitious social event drag racing has seen for decades. That is of course the 2014 BDRHoF Celebration Gala Awards Dinner being held at the Savill Court Hotel, Windsor Great Park on November 22nd. The Celebration part of the event is marking 50 years since Sydney Allard organised his First British International Drag Racing Festival. However the main awards focus on the pioneers being inducted into the Hall of Fame this year. Sponsor of these awards is the Santa Pod Racers Club. At midnight on July 11th 2014 BSM and 7.00pm EST 2014 in the USA, the BDRHoF announced its new inductees – Gerry Belton, Russ Carpenter, Don Garlits, Dennis Norman and John Whitmore. More details about all of them can be found on www.britishdragracinghof.co.uk. We congratulate every one of them. Following the initial sponsorship of the event from Beech Underwriting and Flint Insurance, Lucas Oil Products UK announced its support. Les Downey is Managing Director and Director of European Operations for Lucas Oil Products UK that he established back in 1998. He has been associated with UK drag racing for many years and at the Savill Court he is hosting the welcome drinks for guests as they arrive ready for the Awards Dinner and supplying the official ‘goodie’ bag. Les Downey said,

“It gives me immense pleasure to be able to support this much needed prestige drag racing social event and play a part in honoring those who helped get the sport established in the UK. I have made so many friends during my involvement with the sport and I look forward to meeting up with them in Windsor”. “But as well as welcoming guests with a drop of wine we will also be involved in another aspect of the event to be announced on the night. It promises to be an evening to remember and set a new standard in hospitality that can only benefit the sport of drag racing over the next few years. It particularly rewarding to be involved in the event that also celebrates 50 years since Sydney Allard organized the First British International Drag Festival”. Anticipating that the Gala Awards Dinner would be a sell-out event, the BDRHoF decided to arrange an additional opportunity for fans to meet Big Daddy Don Garlits during his 2014 trip to the United Kingdom. It is being held at Santa Pod Raceway and includes refreshments, a signed copy of Don’s latest book ‘Don Garlits and his Cars’ plus the opportunity to shake hands with the great man and take part in a Q&A session. It is an exclusive event with no more than 50 tickets being made available. Sponsors of the event are UK-based American drag racer Julie Braskett and long-time BDRHoF supporters US Automotive. The event is ‘Afternoon Tea with Don Garlits’ held in the Quarter Mile Club VIP Centre at Santa Pod Raceway on the afternoon of November 23rd starting at 2.30pm. Tickets cost £35.00 (booking fees apply). They sold out very quickly.

Julie said, “Having grown up in a drag racing family from Southern California, and recently relocating to the U.K., I find it rather astounding that now on this side of the pond, I am preparing to meet one of my father's idols. Don Garlits is "The Big Daddy" of them all. A pioneer and a true legend of the sport. He was the driving force, the inspiration, and the very reason my father became a drag racer. This is the reason why I am committed to continuing the Legacy, in my father's name. I would like to thank the BDRHoF from the bottom of my heart, for welcoming me with open arms, and for the honour, and privilege of sponsoring such an occasion”.

Stewart Bassett of US Automotive said, “We have supported the British Drag Racing Hall of Fame since its inception and its growth in status over recent years has been very rewarding. Apart from Bonneville being cancelled, it’s been a great year for all of us at US Automotive. Being able to bring Rat Trap and Pure Hell to Dragstalgia was a real highlight and the opportunity to sponsor and host an appearance of the man who has to be the most influential in the sport’s history is the icing on the cake. We are all looking forward to meeting a legend”. Custom Car Magazine, in partnership with Real Steel, joined the list of companies involved with the Gala Awards Dinner. They are sponsoring a 16 page table programme in the form of a mini Custom Car Magazine, featuring the menu, time table and information about the award winners. A great souvenir. Editor of Custom Car Magazine, Dave Biggadyke said, “We are proud of our association with drag racing over the years and would like to thank the British Drag Racing Hall of Fame for giving us the chance of getting involved in this magnificent tribute to the pioneers of the sport – particularly as this year marks 50 years since Sydney Allard organised the First British International Drag Festivals”. “It is fantastic that one of the men at that series of influential drag racing meetings, Don Garlits, is to be at the Gala Dinner. He has stamped his mark on the sport in a manner that nobody else has equalled. I would like to thank Charles Pinion of Real Steel for joining us as co-sponsor”. Robin Jackson, Press and Public Relations Manager for the BDRHoF says: “Having Custom Car Magazine involved with this event is very fitting. In media terms there can be few publications that have equalled the support and exposure they have given drag racing since 1970. The special mini replica of the magazine on the dining tables will definitely become a collector’s piece. On behalf of the BDRHoF I thank both Custom Car and Real Steel for their support”. And the support keeps coming in. With a substantial four figure sum, the National Street Rod Association UK (NSRA) joined the list of those sponsoring the Gala Dinner. Jason Hollamby of the NSRA said:

“We have recently been working with the British Drag Racing Hall of Fame linked to our involvement in the Dragstalgia Meet at Santa Pod. We really admire what they are doing and the way they go about it. The NSRA Hall of Fame was established in 2012 as part of the NSRA’s 40th anniversary with the aim to recognize significant contributions or achievements from people or vehicles within the hobby, so there is much synergy between our two organizations – both of which are truly national bodies. We are keen to develop this obvious common ground and our sponsorship of this special event is hopefully just the start of a long term relationship”. BDRHoF Chairman Stu Bradbury said, “One of the most costly and important requirements for a successful Awards Event is installing the right Audio Visual support. Julian Parsons and AMP Audio Solutions will be providing this for the Gala Dinner. Most of you will know Julian from Nitro FM at Santa Pod. The not insubstantial costs are being sponsored by the NSRA this year and we offer our sincere thanks. Working with the NSRA to develop Dragstalgia has been a pleasure. Drag racing is the traditional hot-rodder’s sport and hot-rodding is the very foundation of drag racing. Most drag racing pioneers are hot-rodders at heart – including me”. Along with Don Garlits and his family many other special guests will be joining those assembled at the Savill Court Hotel to celebrate the pioneers of our sport. They include Guy Loveridge, Chairman of the Guild of Motoring Writers, Doug Hill, Museum Manager, National Motor Museum, Beaulieu, and Lord Montagu’s Chief Engineer, Ron Hope of Rat Trap Racing and President/CEO of CARS Recon Inc., several guests from Lloyd's of London, the top management teams from Santa Pod Raceway and York Raceway plus others whose names are yet to be announced. While Don is in the country he has been invited to quite a few functions. These include dinner with Lord Montagu’s son Ralph at Beaulieu Palace on November 24th (he will be at the museum in the afternoon so as the museum is open as normal you might glimpse the party viewing the exhibits); the International Historic Motoring Awards dinner at the Renaissance Hotel, St Pancras; lunch at the RAC Club in Pall Mall hosted by Ben Cussons, RAC Board Member and Chairman of the Motoring Committee; and an exclusive trip around the Lloyd’s of London Building including a special presentation by Rupert Atkin, Deputy Chairman of Lloyd’s; plus a visit to Nick Mason’s private collection of cars if it can all be fitted in to the busy calendar. Alamo Rent a Car is providing the transport and Robin Jackson will act as tour guide.

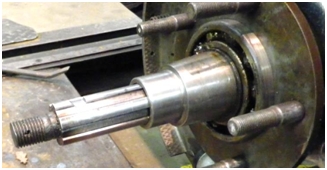

The British Drag Racing Hall of Fame announced that it has nominated The Don Garlits Museum of Drag Racing to be honored with the “Museum Collection of the Year Award.” The Museum Collection of the Year Award is connected to the International Historic Motoring Awards, a prestigious automotive event which honours a number of individuals and groups each year for contributions and achievements in several categories. The Allard Chrysler Restoration Project was nominated in two categories in 2013. The winners will be honored at the St. Pancras Renaissance Hotel in London, England on November 20, 2014. The Don Garlits Museum of Drag Racing has long been a destination for drag racing fans, worldwide. Don’s contribution to the preservation of historic drag racing vehicles, and not merely his own, as well as uniforms, helmets and other memorabilia is a major reason why the British Drag Racing Hall of Fame chose to nominate the museum for this honor. Click the link and view the progress of the Don Garlits Museum Of Drag Racing, nominated as the 2014 Museum or Collection of the Year: www.historicmotoringawards.com. Wednesday 4th June 2014: January to May. Well – I seem to have missed out a blog again. Must be an age thing so this one is a ‘Super Blog’. On December 29th an ACAG team assembled in the workshop of the National Motor Museum, Beaulieu. The first job of the day was to enhance the RHS half shaft with an extra safety mechanism. It had previously been welded by Andy Robinson at the thread end (it had been broken for years) and, although there was no way the wheel could break loose if the weld failed, it was felt that an extra precaution would not be a bad thing. It would also protect in the case of bearing/circlip failure.

We set about the task by grinding a couple of slots in the axle shaft and drilling corresponding holes in the cover (see left). Flat ended M8 Allen Key grub screws were used to secure the cover to the shaft.

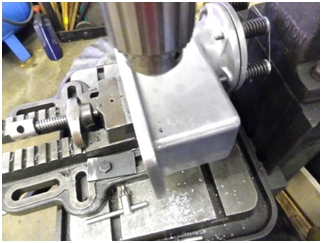

Paul Stubbings also made a suggestion to improve the draining of fuel from the blower after shutdown. A small drain hole was drilled and thread tapped in the base of the blower pop-off valve side-plate at the front end (see right). An M8 Allen Key head screw with a copper washer was installed as the blank. This proved to be a very simple but useful modification. After shut-down the rear of the dragster can be jacked up and the drain plug removed to drain surplus fuel. Turning the engine on the starter button with fuel shut-off closed and mag off should clear the blower of any further excess fuel, driving it into the drain hole. We also addressed fitting our ex Dave Gibbons chute. Up until now the pack had just been padded out with material for effect. It was a tight fit and tougher eyelets were required, but as we did not need the spring loaded drove (we do not envisage using the chute to stop the dragster; just for display) this was removed and placed in storage. We had previously identified that the length of the on-board fuel pipe linking the injection system to mobile starter trolley union was too short and this resulted in stressing the union joint so that it leaked – a regular occurrence during 2013. Plans were made to replace it with a longer pipe but unfortunately this was not the end of the story as readers will find out. We took the clutch pedal to Nick Connor’s workshop so that he could fabricate an extension that would facilitate more room for movement in the cockpit. At the time it hit the clutch cover when fully depressed. Again this proved to be just the start of a series of discoveries about the transmission problems on the dragster. Jan 19th saw our first Beaulieu get-together of 2014. Our main focus was to take the clutch out so that we could reduce the number of springs from three sets of three to three sets of two – the idea being to produce a softer clutch action. With the clutch unit out, using a hydraulic press we were able to expose the springs and remove one from each set of three. The unit was then re-installed to the engine. We had a good look at the tacho that had been giving spasmodic readings during 2013. We spotted a mechanical problem with the meter and further tests were needed. Feb 23rd saw an ACAG Team gather at Beaulieu again. Gareth brought along the clutch pedal that had been strengthened by Nick Connor. The new extension was drilled ready for the retaining pin and then attached to the gearbox shaft. But we found that the pedal shaft in the gearbox was slightly bent so we had to find a replacement shaft. We removed the RHS exhaust manifold and gasket that was leaking on one side. We found that something quite unexpected. Some manifold retaining bolts were leaking coolant. Checking the LHS resulted in similar leakage. These bolts were taken out, the coolant drained and the bolts re-installed using thread lock. The headers and exhaust gaskets were cleaned and the gaskets heated to soften them before installation.

March 16th saw the ACAG Team gather at Beaulieu again. We had obtained two replacement shafts to replace the bent one; one for a Ford Pilot (this is the box we had been led to believe is on the Allard) and one was a Mercury fitment (recent work leads us to believe the box fitted was used for a left-hand column gear change drive American vehicle). On arrival they both appeared to be the same shaft with slightly different attachments. Once we got the existing shaft out (not easy) there was a difference between that installed and the replacement shafts (see left). Both replacements were 7/8 inch diam while the existing one was ¾ inch diam. It looks as if at some time the existing shaft had been modified – probably as part of trying out different clutch units. While the clutch was exposed other measurements were checked and these seemed to be in order but the clutch was still very severe so we decided to order a saloon car clutch. It is something we had looked at earlier. The parts ordered by US Automotive were Schiefer clutch disc 706-0009, 11 inch diameter, plus 1 3/8 inch x10 spline input shaft to fit Ford manual gearbox applications. The original clutch on the dragster was Schiefer so it is in line with keeping the car in original status. We also found a small crack in the gearbox casing. So we decided to source a replacement casing and rebuild the gearbox using the correct sized 7/8 shaft and the parts in the existing box.

Ford gearbox specialist Alan Brock found a period correct unit in the USA and had it shipped to his base in Bedfordshire where he had it blasted before removing the old shaft and re-shimming it as necessary. He then cleaned it ready for us to work on. We also looked at the clutch pedal mechanism. It came straight off the shaft with no heel rotating point apart from the floor or extra levers in the linkage to magnify pedal pressure. It meant that a lot of lateral force was used rather than rotational. Looking at the pedal fitment in the Commuter dragster that is currently on display at Beaulieu, we developed some ideas for improving the situation. However, we decide to delay further work on the transmission and focus on getting the car ready for its first test fire-up of the year on March 30th. So we put things back together without the clutch shaft installed. And as we did not plan any immediate work on the clutch we re-installed the left hand side cockpit floor. Rubber matting was installed on both shelves of the recently painted starter trolley for protection, grip and easy cleaning. We also had new batteries donated by Yuasa. These were YBX 5334 units, 95 Ah, 830A as recommended by Yuasa’s tech team. We only needed one on the trolley so we now had a back-up already charged. It should give more power on starting and more starts per charge. We replaced the crocodile clips with proper battery post fitments. Battery clamps were installed to hold it firm in the trolley and an isolator switch completed the job. The inlet manifold was removed because a leak had been spotted at the final fire-up of 2013. Gaskets were cleaned off and it looks as if the leak might have been between the spacers and the engine. New gaskets and gasket sealer were installed and the manifold replaced. More sets of replacement gaskets were ordered via our parts buddies US Automotive. After the manifold had been installed we fitted the booster gauge using one of the port injection points. Hopefully this will give us more information when the engine is running. We were unable to re-install the tacho as it was proving difficult to fix the damaged windings. Leaking core plugs on the left hand side of the engine were cleaned and re-sealed without removing them. We may have to replace these in the future.

It was Kev’s birthday weekend and he bought in some fantastic Ally Cake Pops in the shape of the dragster. We felt like cannibals eating our young but as well as being works of art they tasted good.

March 30th saw us back in the Beaulieu workshop. One of our supporters, Steve Clark at Nimbus, kindly donated a System 1 billet spin on oil filter Part Number 209-561B. On advice from Nimbus we had chosen the 3.75” diameter filter which is slightly longer than the original. We also changed to a 45 micron element (part number 208-560) for use with the 60wt oil. This was installed and it meant that we would be able to drop the filter after a run, clean the mesh after checking for debris and re-install after filling with oil. Much better than just replacing the filter without having the ability to check for debris unless the old filter unit is destroyed.

When we took off the rocker covers we discovered quite a bit of corrosion that had to be cleaned off with spray, brush, Scotchbrite and cloth. We think it had been caused by condensation and/or nitro in the oil. We have decided to revert back to using Lucas blue 50 Plus Racing Oil with Organic Moly. We were also advised to use Lucas oil stabilizer as well. As an added precaution we decided to change the oil more frequently and clean down the rockers as part of our post cackle session drill. For the pending test fire-up engine oil was applied to rockers before covers and new gaskets were reinstalled. We decided to ask Nimbus for some Torco MPZ. Plugs were removed, checked, cleaned, gapped and replaced after spraying WD 40 in bores. Oil was drained and replaced. WD 40 was sprayed into fuel pump. Evans fluid was topped up. For the first run of the year we ran our methanol/petrol mix from the on-board fuel tank. The starter trolley was just used for the battery power. The car was on rear axle stands outside the Beaulieu workshop. The Digital temperature gauge was attached for block temperature and the laser gun made available for outside block and header readings. All body panels were off so we could check for leaks. After a quick starter motor turn with the fuel shut-off open to get fuel into the injectors, the mag was switched on and the car fired on the second attempt. Unfortunately it had to be switched off after a few seconds due to a fuel leak in the fuel filter container. This was given a temporary fix but we decided to replace it with a direct connection as the fuel filter element failed the nitro test last year. We also drained the residue fuel out of our new Potvin manifold drain.

We went for another start and it fired up first time sounding really great. We didn’t attempt any fine tuning but let it run for a couple of minutes to check for any further leaks. Apart from the fuel filter still seeping fuel all seemed OK. After switch off surplus fuel was again drained from the blower drain and the remaining methanol drained from the fuel tank for use another day. After the team took off the rocker covers to check all was well, we dropped the new oil filter, checked for gunge, cleaned the filter and replaced. We replaced the leaking fuel pipe that Andy Robinson had fabricated using Exact unions. We also went through the full list of checks that will go in the operating guide. During this session we hit problems. Leaking pipes and unions on the dragster’s remote trolley feeds caused problems as soon as we put any pressure into the methanol feed. Despite many attempts to rectify the situation, a decision was made to abort the original nitro test schedule and go for a couple of methanol runs fuelled from the on-board tank. We took measurements of the leaking pipes and unions required and made plans to fabricate a completely new set.

The methanol run went well and put some heat into the motor. We left it to cool to a manageable temperature and then removed the rocker covers so that Gareth could set the valve lash. They were quite a bit out. Oil stabiliser was added to the oil and Torco MPZ used on the rockers. New NGK plugs were gapped and installed. A second run was carried out and the engine sounded much sweeter but we had a leaky rocker cover spacer. After the run the covers were taken off again and new gaskets and sealant applied. The plugs were checked and the oil filter dropped again. All looked OK. Methanol was drained from the tank. Our first public appearance of 2014 was on April 18th at Wheels Day held on Dunsfold airport - the home of Top Gear. It was the first day of the Easter break and the event was organised by Surrey Street Rodders - the 40th anniversary of the show. This was the first time at this venue for the show that had previously been held near Aldershot. But there were only two narrow road access points and huge traffic jams built up with queues starting before 8.30 am. By mid-morning the jams were so long the police ordered the organisers to let people in FOC to speed up traffic flow. 23,000 attended and many turned back because of the jams. It demonstrates the appeal of the event.

The dragster was pitted in front of the National Motor Museum, Beaulieu display point and attracted big crowds. The team was in white overalls rather than the ACAG T-shirts and were featured in several video and photo shoots. Once pressure was put into the trolley fuel system a couple of unions needed tightening but otherwise it was all OK. With Jon Godman in the driver’s seat while Gareth tuned the idle settings the methanol start was carried out. All looked good for our methanol-nitro-methanol fire-up at 2.00 pm. I was interviewed on stage by event commentator John Price who later brought the mobile mic to our car for the 2.00pm start. This went well and startled a few people who had not heard or smelled a fuel dragster before. We drew a massive crowd as the photo shows.

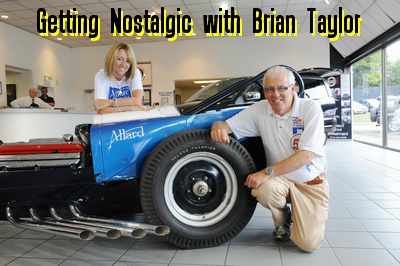

This link takes you to a video of the nitro fire-up All in all a good day for the crew, the National Motor Museum, Beaulieu and spectators. Taking history to the people – particularly working history – is an important part of the National Motor Museum, Beaulieu’s strategy. 2014 Allard Chrysler Dragster planned Appearances in 2014 April 18 - Surrey Street Rodders’ Wheels Day, Dunsfold (COMPLETED) Our appearance at Dunsfold was reported in Nostalgia Drag World http://nostalgiadragworld.com/v2i5allardbriantaylormelanie.php If you want more details about the work carried out so far this year follow the links to updates for March and May. Additional news

During a recent visit to the UK our good supporters Cliff and Sharon Watts gave us another donation – this time something for our box of goodies. It is a 1970s vintage crash helmet complete with peak and visor. It previously saw use with the Uncle Scrumble competition altered that raced in the UK during the 1970s. They have now returned to their home in California. Thank you both for your continued support. Media Coverage

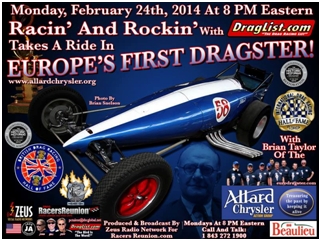

The 2014 January issue of Custom Car saw a fantastic feature on the dragster with photos by Matt Wood taken at the 2013 Dragstalgia event and words by Keith Lee. We even had a centrefold pull out of Nitroman next to the car. We also had a slot on Racers Reunion Radio in the USA. Presenter John Bockelman talked about the dragster and our project in glowing terms. Iris Page Achievement Award We were presented with an achievement award for work carried out on restoring Europe’s first dragster - the Iris Page Memorial Trophy. The trophy is awarded to ‘the racer or team or individual who has contributed most to the sport over the previous 12 months or achieved their own personal goals against all the odds thrown at them’. It is satisfying that people in the sport see us in this category. 2014 BDRHoF Celebration Gala Dinner As most of you know I also handle the Commerce and Marketing functions for the British Drag Racing Hall of Fame (BDRHoF). On May 19th the BDRHoF announced more support for the event, this time from the Flint Insurance Group that is sponsoring the table wine and the Public Liability Insurance required for the function. More sponsors will be announced soon. Together with the induction of the Hall of Fame’s new members for 2014, the event celebrates a landmark, half-century anniversary. In 1964, the International Drag Festival gave Britain its first full taste of the American sport of drag racing. A joint-venture between Sydney Allard and Wally Parks, president of America’s National Hot Rod Association, the ‘Dragfest’ brought a team of leading US racers of the day to race on airfield sites across England.

Already the foremost star among them was ‘Big Daddy’ Don Garlits, who in the ensuing decades would become the true titan of the quarter-mile – not merely the greatest drag racer who has ever lived, but a touchstone figure who would define the very landscape of the sport we know today. So it was with great excitement and pride that at 2.00 pm on Saturday May 24th the BDRHoF was able to give the fantastic news that the King of Drag Racing – Don Garlits – is to fly in from the USA to attend the Gala Dinner. At 82 years of age, Don continues to serve as Chief Executive of the Don Garlits Museum Of Drag Racing and the International Drag Racing Hall Of Fame, both based at Ocala, Florida. Daughter Donna is General Manager and Chief Financial Officer of the Museum. While not (currently) active in competition, Don has never ceased his on-track exploits and innovations. Within the past month he has established a new quarter-mile record for a battery-powered electric dragster (7.25sec/184mph) and is intent on breaking the 200mph barrier for the class. Further news of the Gala Night and of Don Garlits’ UK visit will be released on www.eurodragster.com and tickets for the occasion may be obtained by contacting the Hall of Fame via its website. This year’s new Hall of Fame inductees will be announced during the Dragstalgia event at Santa Pod Raceway, 11th-13th July.

Still about the Gala Dinner, early this year the British Drag Racing Hall of Fame (BDRHoF) announced the introduction of two new annual BDRHoF Awards for photographers and writers. Open to professionals and amateurs, they celebrate the importance of the media in promoting our sport along with the crucial role played by Sydney Allard as the ‘Father of British Drag Racing’. The trophies are sponsored by the Allard Motor Company operated by Sydney’s son Alan and his grandson Lloyd. One will be presented to the writer of the best book, article, blog or feature on British drag racing published in print or on-line during the 12-months ending July 2014. This is in association with the Guild of Motoring Writers and the Chief Judge is the Guild’s Chairman Guy Loveridge. The second will be presented for the best photograph featuring British drag racing, either published in print or on-line during the 12 months ending July 2014, or remaining un-published. This is in association with Octane Magazine and the Chief Judge is Octane Columnist and Classic Car Collector Nick Mason who will be joined by Octane Art Editor Mark Sommer. So the competition has already started with many photographers and writers owning photos and/or articles taken or written from August 2013 onwards. Many have already sent in their entries. You can enter as many pieces of your work as you like, but each entry must be accompanied by a completed entry form to enable the judges to collate them accurately. The entry form can be downloaded, completed and then sent back by e-mail to with attached article or photo files in Word or pdf form and photographs in jpg form. These forms can be accessed by selecting the Allard Award Entries tab from the menu on www.britishdragracinghof.co.uk/allard-award-entries. These new and prestigious awards will be presented at the BDRHoF Gala Awards Dinner on November 22nd 2014 held at the Savill Court Hotel, Windsor Great Park. Wednesday 4th December 2013: August to December. Here we go with my pre-Christmas blog. The last one was written just after the Santa Pod Dragstalgia event and what a great success story that was this year. After this appearance and fire-up of Europe’s first dragster the ACAG team took a bit of a break. Many had other projects they needed to work on and family holidays came to the fore. The dragster remained on display alongside many famous Grand Prix cars at its true home, the National Motor Museum Beaulieu. I went down and sorted out all the bits and pieces that had been delivered with the car after Dragstalgia many previously with Bob Roberts and Andy Robinson Race Cars). These were taken to the storeroom – marked up as Allard dragster stock. Some parts and equipment still remained with Nick Connor in Reading who was working on the mobile starter trolley.

Syd McDonald called in to the museum to carry out more detailed work on the chute pack. And thanks to Dave Gibbons we also located a chute. I also made another trip to pick up the remaining parts and equipment from Nick Connor. He retained the mobile starter trolley to manage the final paint job. I had two large ‘bonnet 58’ decals made up for applying to the sides of this unit.

We continued to raise funds – now for operational costs as well as the restoration work. Graham Durbridge had donated the original artwork for his two Ally CARtoons. I had them mounted, glazed and framed as a matched pair ready for auction. The highest bid was £250 for the pair from Ingrid Chesworth as a present for husband Martin. Thanks Ingrid. Your name has been added to our Roll of Honour. More funds were raised by the National Street Rod Association (NSRA). After Dragstalgia Pike Murray took away our stock of old hot rodding magazines and sold them at their own functions. This raised nearly £90.00. Thanks Pike and the NSRA. The NSRA is now on our Roll of Honour and a link to their website can be found on the links page of www.allardchrysler.org. On the sponsorship side American company Mr Gasket joined our gang of supporters. The Mr Gasket products used on the Allard Chrysler include valve cover gasket sets and a Mr Gasket oil dip stick. Another link to Mr Gasket comes via our Bedford -based components partner US Automotive; the number one Mr Gasket distributor in UK. And our North American Patron is Traci Hrudka, Chairman of the Quarter Mile Foundation and Project 1320, a Charitable Trust logging the history of American drag racing in a series of films for television. Traci is the daughter of Tom Hrudka (one of the Mr Gasket company’s founders) and she was Sales and Marketing Manager for Mr Gasket 1982-1997. In 1993 she was named the Performance Warehouse Association Person of the Year. I can’t quite remember who introduced Traci to our restoration project. I think it was legendary drag racing commentator Jon Lundberg or Carl Olson. Whoever it was did us a big favour because she is an explosion of enthusiasm Building awareness of our restoration project in the USA has been vital to gaining sponsorship from many American suppliers and Traci has played an important role in this. And our good supporters the British Drag Racing Hall of Fame donated a further £250 from a long lost BDRA fund that was finally released. The ACAG and the BDRHoF work together wherever possible to promote the ‘Nostalgia Drag Racing Scene’. Still with ACAG supporters our major sponsor F&A Racing won the last FIA European Top Fuel Championship round of the year at Santa Pod in September so many congratulations to Chris and the team. Renting an RF Motorsport car this year it turned out to be a hard slog over the weekend but it paid real dividends. I have been checking out who will be wearing the ACAG shirts and special overalls in our winter work/show team and the support crew for 2014. After three years camping out at Andy Robinson Race Cars the regular maintenance work will now be carried out in the Beaulieu workshops at the museum – still on a voluntary basis and at weekends. Those joining me as volunteers so far are:- Kev Roberts, Gareth Kent, Ian Jones, Mike Kason, Liz and Peter Rowland (shows), Paul Stubbings, Dave McDonald, Syd McDonald, Nick Connor, Stu Bradbury, Martin Dunks and Ian Coulsell. So most of the original team remain in place but we are still looking for more volunteers – particularly anyone within a 1 hour drive of Beaulieu. November 10th saw the team get together for the first time since Dragstalgia. The main focus of the day was to discuss and plan the work required on the dragster during the winter. The overall strategy for 2014 is to get the car so that it can be paraded under its own power rather than just cackle as a static exhibit. The second purpose of the get-together at Beaulieu was to prepare the dragster for its appearance at the International Historic Motoring Awards function in London on November 14th, for which the project had been short listed in two categories. Those joining me at the National Motor Museum, Beaulieu on November 10th ready for physical and brain exercises were Kev Roberts, Gareth Kent, Paul Stubbings, Syd McDonald, Ian Jones, Nick Connor, Martin Dunks and new comer Ian Coulsell. His son Mark had helped us out at the Nostalgia Drags meet earlier in the year. Several topics were reviewed after the dragster was given a good polish and shine plus we identified a few other items such as loose right hand axle mount bolts. And at long last we were able to apply the decal of our major sponsor F&A Racing on the engine firewall.

After the polishing the first thing we discussed was completing the paint on the starter trolley. Nick Connor will get this finished ready to bring to Beaulieu for re-assembly during our first Work-In sessions of the winter. But there were two potentially big jobs to do. The first was to further modify the clutch so that the power transfer on gear change would be gradual enabling gear changes to be more manageable for parading. Over the months several ideas had been discussed but thoughts during the November 10th get together seemed to offer an easier path.

The clutch pedal position and operational arc (throw) needed to be addressed. Martin sat in the cockpit to test the current set-up. The cross shaft seemed to be slipping so this needed to be investigated with the clutch out. The pedal also needed to be spaced out to the left hand side of the cockpit so that it did not foul the bell housing when fully depressed. This would mean slight modification to the floor panel and cross-shaft. The clutch spring pressure needed to be lightened. Current thoughts are to remove three of the springs in the clutch (three sets of three in the 3 lever unit reduced to three sets of two). In theory this should reduce the spring pressure by 33.3 per cent. The clutch would need to be removed of course but the team figure they can now do this without removing the engine. It is still a difficult job because everything between the rear axle and the clutch adapter needs to be moved towards the rear. The second potentially big job concerned one of the half-shafts that had been welded close to the outer-shaft thread. This right hand side wheel assembly was dismantled and the thread, along with its role in wheel retention, thoroughly investigated. The team’s thoughts were that if the weld broke the wheel would still not break lose and a further safety device could be fabricated as an extra precaution in the event of the weld failing. Photos were taken and Martin checked out these ideas with Andy Robinson Race Cars who carried out the original weld. Andy gave the proposed modifications the thumbs up. On re-installing the half shaft/wheel assembly the brakes were adjusted. This was also carried out on the left hand wheel. It was discovered that this adjustment could be made with the wheels on. The engine oil was drained to check its condition. Around 1 pint of nitro had settled in the bottom of the sump. This was separated and the good but used oil replaced in the engine. No metal was found. From the condition of this oil it seems that only a light service would be necessary. However, it was decided that before itemising the service jobs it would be a good idea to fire-up the engine for a short warm up run and then carry out a leak down check. This would indicate whether we needed to take off the heads and check the pistons. Pre warm up checks would include topping up oil, changing plugs, spraying WD40 in bores through plug holes, checking coolant levels, checking fuel system unions (clearing out ptfe residue and replacing with red thread lock, taking the blower back plate off to check for residue fuel and check blower lube level, completely drain fuel tank and refill if going for a nitro run, WD 40 fuel pump, lube rockers. After the clutch and half-shaft work have been completed along with any general service work, other jobs would include:-

So a very rewarding day with lots of progress, helped along by Syd Burgers and Mrs Syd bread pudding of course. I have since prepared a series of work schedules, with job time and man-hour estimates. We plan to commence these jobs between Christmas and the New Year – starting with the clutch modifications. I’ve started to rough out potential show appearances for the winter and next year. The Surrey Street Rodders have moved their big event to Dunsfold on Good Friday 2014. I have said that we will provisionally be there. Just had the Festival of Speed dates confirmed – June 26-29th. The Allard has been put on standby for that and we will be at Dragstalgia on 11th to 13th July. We have also been pencilled in for Team Member Gareth Kent’s wedding in 2015. We are the ‘something borrowed and something blue’ bit. Bow ties with the overalls I think. But we had an unscheduled appearance in November. In October the ACAG received the following e-mail from the International Historic Motoring Awards 2013. I'm delighted to tell you that, following multiple nominations, the Allard Chrysler has been shortlisted in the Restoration of the Year category in the 2013 International Historic Motoring Awards in association with Octane magazine and EFG International private banking. And - also as a result of multiple nominations - you yourself have been nominated in the Personal Achievement of the Year category! Many congratulations on being nominated by so many people, and on being shortlisted - and good luck in the judging!

Wow! To say I was ‘gobsmacked’ understates how I felt. I had to phone Doug Hill, Museum Manager at Beaulieu to check that it wasn’t a hoax. The Awards celebrate the very best of the best in this £multi-billion international industry. Nominations are received from around the world, and from a variety of disciplines, and the geographical spread of the historic motoring movement is emphasised by the list of finalists each year, which includes events, companies, cars and individuals from across Europe, the USA, Asia and Australia. It is the benchmark by which the world of historic motoring judges itself and now established as the most prestigious celebration of this global industry. The Awards showcase the success and dedication of the people and businesses that make it all happen These are the categories and, as the e-mail indicated, out of hundreds of entries the restoration of Europe’s first dragster had been included in the short lists of two of them.

Those judging reflect the prestigious nature of these awards; Derek Bell, Horst Brüning, Ian Callum, Robert Coucher, Dick Crosthwaite, Berthold Dörrich, Tony Dron, Ed Gilbertson, McKeel Hagerty, Simon Kidston, Jay Leno, Nick Mason, Jochen Mass, Bruce Meyer, Lady Susie Moss, Dr Franz-Josef Paefgen, Patrick Peter, Murray Smith and Peter Stevens, Duncan Wiltshire (chair of Judges) Being short listed in this company is a tribute to the ACAG team and all of those who have supported us during the last five years. On announcing that we had been nominated we had loads of congratulatory e-mails. Here are just a few. Congratulations, and good luck in the voting – Carl Olson Superb Mate! I cannot think of a better person and team that deserve this more. I am so very proud of you and your crew for staying true to your mission and pulling through and making Ally look like a new Diamond! Time to go and get Margarita/s and celebrate! – Traci Hrudka Most richly and well-deserved by all hands. Congratulations to the entire ACAG Team! – Jon Lundberg I just wanted to say congrats on the nominations. Drag racing is too often overlooked in the 'land of mainstream motorsport' and it's fantastic that you and the team have got some recognition for the remarkable efforts over the last (how many?) years! Well done! – Nick Davies Many congratulations on being nominated. You and the ACAG team deserve to win. That would be icing on a very large, already heavily iced cake! We'll done. – Nigel Holland. Just to add my congratulations on your nomination. I hope you receive the award as you really deserve it, not just for ACAG and the dragster restoration but for your book and all the behind the scenes work you do to further British Drag Racing. – Peter Crane The winners of the International Historic Motoring Awards 2013 were announced at a gala dinner in London on Thursday, 14th November at the magnificent St Pancras Renaissance Hotel. Thanks to the National Motor Museum, Beaulieu and some hectic cleaning and polishing by the ACAG crew at Beaulieu on November 10th the dragster looked amazing displayed by the main entrance of the hotel. The ACAG Guard of Honour (overalls caps IMI ties and pipes of course) consisted of Kev Roberts, Syd McDonald, Stu Bradbury and Bev Bradbury. They managed to negotiate the best position and during the evening many admiring glances and complimentary remarks (like WOW!!!) came the crew’s way. We were next to a small racing car that used to be driven by someone called James Hunt.

So although we didn’t win any of the official awards we did win a lot of new friends and made our project even more famous. The gala dinner was attended by the rich and famous from around the world. Murray Walker MBE and Sir Stirling Moss were in attendance. I was in the very pleasant company of National Motor Museum Trust Director of Collections Andrea Bishop and Corporate Partnership Manager Heather Reid. It was great to see our dragster up on screen as the nominations were read out. More details about the awards are on www.historicmotoringawards.com On the general nostalgia drag racing scene I have continued to help Stu Bradbury at the British Drag Racing Hall of Fame (BDRHoF) with press release work. With Robin Jackson joining the BDRHoF Team I can hopefully re-focus on the Allard Project. There have been exciting developments at the BDRHoF and details can be found in the December 2013 issue of our on-line publication ACAG Update via this link. Likewise I have been pleased to be involved with the 2014 Dragstalgia plans and this looks like being very special. Sunday 4th August 2013: April to July. I seemed to have missed a Blog in March so I have some catching up to do. I’m not sure how that happened but let’s start the catch-up by briefly reviewing some April highlights. APRIL Although there was plenty of other work to complete, the main aim for the April 7th Work-in day at Andy Robinson Race Cars was to go for another fire-up and test the latest developments in our methanol – nitro switching mechanism, plus carrying out more engine-run gear changes. Before that we replaced a core plug that was blown out during the previous test in March. We were still having problems with overheating and it was generally felt that it was the pressure caused from steam that forced it out because the Moroso block-fill only goes half way up the core plug level. With the dragster up on axle stands the fire-up and methanol/nitro switch went well although we still had a problem with the engine getting hot very quickly and boiling the cooling water. This time we left the filler caps off to prevent pressure build up and topped up water as necessary during the run. Gear change checks went well although we did have a very heavy clutch. After the run the head was torqued down to 110 lbs ft. A cylinder compression check was carried out to check for any gasket blows that might be causing the water boiling and all looked good. We also started to look at ignition timing to reduce heat. At the time the ignition was set to about 30 degrees advance; our best guess from experience as to what would work with our 60% methanol/40% nitro mix being used at the time. April 21st saw us continue the restoration. Good progress was made on several fronts. The magneto casing was marked out in 5 degree segments - advance and retard either side of our existing 30 degree setting. This was to enable us to tweak the timing to aid cooler, more consistent running. We decided to further address the engine cooling issues by testing Evans Waterless Engine Coolant that reduces the coolant boiling temperature. We continued to dial in the timing on April 25th. With the Magneto timing advanced a little (5 degrees), the dragster fired up straight away. There was less steaming this time and the engine was run on methanol and the nitromethane mix. We appeared to be going in the right direction so we continued down that track with a further fire-up. MAY

May 5th saw the timing advanced a further 2.5 degrees (now reading 42 degrees). The sequence was double checked by viewing the flywheel timing marks and cranking the engine on the starter motor. The nitro percentage was increased to 66 per cent. The run went well and the switch from methanol to nitro was smooth (good header flames). We continued with other work and also had a chance to take photos of the day’s crew in the new Allard Lucas Oil T-shirts (only £15.00 each plus P&P). L-R: Brian Taylor, Nick Connor, Syd McDonald, Paul Stubbings, Andy Robinson, Stu Bradbury, Martin Dunks, Gareth Kent and Bob Roberts in the new Allard Chrysler Lucas Oil T-shirts. Much was achieved on May 12th. We installed a cooling system header tank to improve the cooling. The dragster had several cooling systems during its life time and although this version is not as original we think it is in keeping with the ethos of how the car was developed. It is also small and unobtrusive, being hidden under the top cockpit panel within the cockpit area. The car was started on methanol, switched to nitro and then back to methanol again on several occasions. Each run was about 2.5 minutes and cool down time was managed at around 1 hour. The nitro flames and cackle sounds were much closer to where we wanted to be and the new coolant system seemed to work well. JUNE June 2nd saw us back at work. The engine firewall was installed. This is one of those critical stages that can really make a difference to the look of the restored dragster. Back in the early 1960s the firewall was the only surface where advertising was allowed due to RAC regulations. The Allard had several different decals affixed here during its life including Castrol, Wynn’s and Valvoline. None of these companies have supported our restoration so we will follow Sydney Allard’s view of putting in place the logos of our major supporters - F&A Racing, Lucas Oil and Andy Robinson Race Cars. You can see how the restoration faithfully reflects the original when you compare a recent photo with one taken back in the early 1960s.

On the left we have the restored dragster. The original is on the right. The last fire-up of the day was with all panels on (the first time since the restoration). This link takes you to a video of the event. We were now ready for our first public appearance in the fully restored state; a special Institute of the Motor Industry (IMI) drag racing evening held at Northbrook College, Shoreham-on-Sea airport on June 13th. This continued our partnership with the Institute to promote the motor industry as a career choice.

We took the car out to the car park and fired it up in the afternoon sun before returning it to the workshop ready for a presentation to the students in one of the lecture rooms about its history and restoration. It was then back into the workshop to chat to the students. At 7.00pm the more senior members of the IMI came to view the cars and bikes on display in the workshop. We fired up the dragster again at 8.00pm before moving back into the lecture room for another presentation. Time Travel DVDs No 10 went down well. It covers the role Sydney Allard played in launching the sport. Friday June 14th saw us transport the Allard Chrysler Roadshow to its true home Beaulieu; ready for its official hand-back as a completed restoration project. The Saturday fire-up went well. The engine sounded really crisp and shook the Beaulieu tarmac for the first time in the dragster’s life. Sunday started out a bit damp and got damper for a while. We prepped the car in our pit marquee and didn’t wheel it out for the official hand-back ceremony until just before 11.00 am – the published fire-up time. The fire-up went well and a large crowd enjoyed the sound of a Chrysler Hemi and the sweet smell of nitro in the air. Lots of photos of the car and the team were taken for the press. More chats and then we all drifted across to the Domus for our celebration buffet courtesy the National Motor Museum. I was able to give a proper thank you to everyone involved with the project. Special thanks came from the museum’s Director of Collections Andrea Bishop, Diane Golder who bequeathed the dragster to the museum after her husband Brian passed away, ACAG Patron and museum Trustee Nick Mason and Museum MD Russell Bowman.

VIP Guests and the team are shown in the pic that follows; L-R David Hooper the dragster’s designer, Sydney Allard’s son Alan, me, Diane Golder, Nick Mason, Kev Roberts, Kev’s son Jason, Gareth Kent, Syd McDonald behind Gareth, Nick Connor, Martin Dunks behind Nick, Paul Stubbings, Ian Jones, Bob Roberts. This link takes you to a video of the official hand-back ceremony and fire-up. Back out again for another fire up this time with Terry Clifford’s Rat Trap. More PA interviews with Alan Allard and David Hooper being featured this time along with Lord Montagu’s son Ralph. A good fire-up after an initial pop-off back-fire and the header flames looked and smelled as they should. Commenting on the restoration, Director of Collections, National Motor Museum Trust, Beaulieu, Andrea Bishop says: “As far as I am aware, such a task has never been completed on an iconic exhibit in the UK, by a group of private individuals working in partnership with the museum who own it. The ACAG raised the funds, researched, promoted and publicised the project and provided the expertise and people to carry out the work. It truly is an amazing achievement and a fantastic model for other groups to follow”. Museum Manager and Lord Montagu’s Chief Engineer Doug Hill sent a message to the ACAG Team: Dear All I cannot thank you enough for the extraordinary work you have done on the Allard, and the huge achievement in getting it running. I am amazed at the wealth of knowledge and skills displayed in this project. I cannot thank Brian enough for heading the project, indeed without his tenacity and vision this car would still be sat in the museum with a box of broken bits in store just being a 3 dimensional object, not a living breathing thing. Also thank you so much Andy Robinson for accommodating our car and quietly and calmly giving valuable advice during its restoration. Not only has Beaulieu now gained another fully functional and unique piece of British motoring history, but also a group of loyal and talented friends. The story of this car now turns another page, but does not stop. I am very keen for “Ally” to get out there and fly the flag for Beaulieu and “Dragstalgia.” Thank you all. The NSRA Nostalgia Nationals at Shakespeare County Raceway over June 22nd and 23rd marked an important weekend in the history of the Allard Chrysler dragster. It would be the first visit to the Long Marston venue since 1963 when sprint events were held at the airport. In the Saturday morning I carried out a live interview on the land line for BBC Radio Coventry talking about the dragster and the event and our restoration project. Combined with good local press coverage we managed to help promote the event. The dragster arrived at 10.00 am Saturday courtesy of Polygon Race Car Transport.

We carried out a nitro fire-up in the pits to warm up the engine ready for the ‘cackle fest’ due at 6.30 pm with the Wild Bunch. We had been granted a lifetime Honorary membership of the Wild Bunch and were tasked with leading off the cackle; our first proper ‘cackle fest’ with other nitro cars because previously we had been running methanol at such occasions. This link takes you to a video of the Nostalgia Nats cackle. JULY Dragstalgia 2012 at Santa Pod Raceway saw the first public fire-up of the restored dragster so it was good to take the completed car to Dragstalgia 2013 over July 13th and 14th - to cackle on nitro rather than methanol as was the case in 2012. It also enabled the fans and supporters to get a close view of the completed project with its new chrome and paint. The weather was really hot this year. Santa Pod Raceway provided a pit marquee with space around that was enough for the joint ACAG/British Drag Racing Hall of Fame retail point using Syd McDonald’s easy-up gazebo. His caravan was positioned behind to act as the ACAG hospitality focal point. With the beautiful Commuter dragster across the way it was a good place to be. A test fire-up was carried out in the pits and all looked good. Another warm-up run was carried out in the pits at 6.00pm ready for the on-strip cackle fest at 8.15pm. Gareth Kent took the driving seat for the evening cackle (now fully equipped with period safety wear courtesy Deist Safety, Wild Bunch and Ron Hope), The dragster fired up well and the switch to nitro was smooth. We detached the trolley connections from the car and moved it away to give the fans a good look.

This link takes you to a video of the cackle fest.

We announced another pit cackle would take place around 1.00pm on the Sunday. This went well drawing a large crowd of fans. The rest of the afternoon was spent talking to our visitors, some having their photos taken in the driving seat. This link takes you to a video of the pit cackle. Dragstalgia 2013 was a fantastic event. The weekend was quite successful on the financial front for the ACAG with funds raised from our retail point and a donation from Santa Pod Raceway. We loaded the dragster on to an open trailer and started the long trek back to Beaulieu. I passed it on my way home and the dragster looked quite comfortable on an open trailer in the evening sun attracting many admiring glances. It is now on display at Beaulieu in the company of some very famous Formula One cars. You will find lots more info, photos and video links covering this blog period in the last two issues of ACAG Update here and here. The next IMI Youth Day is at Santa Pod on the Thursday before the European Finals and the ACAG will be helping out with that. The same weekend sees the presentation of the 2013 British Drag Racing Hall of Fame awards so expect to see some faces from the past around the place. Tuesday 2nd April 2013: Winter work, branding, 2013 plans. WORKING ON THE ALLARD CHRYSLER Hi all. My last blog was before Christmas 2012 and things have moved on a pace since then. You will recall that 2012 was spent simply assembling the dragster to prove that everything worked. Final finishing was planned for later so after a full tear down of the completed ‘working dragster’ in early December, we sent out components for paint, chrome and final finishing. Once the pieces had been returned to Andy Robinson Race Cars we started to add the ‘razzle dazzle’ factor – such an important part of drag racing. In fact, back in 1961 Sydney Allard was chastised by the traditional sprint fraternity for the amount of chrome on the car. Our last 2012 ‘Work-In’ day on the dragster was December 30th. Although it was the last in the year it was really the first of the final re-build with cleaning and polishing bits the aim of the day along with starting to build and refurbish small sub-assemblies including some of the recently chromed pieces. The gearbox and rear axles were primed and painted red as per the original car; as were the front and rear wheels.

January 2013 saw the team back at Andy Robinson Race Cars with the first objective of getting the dragster back up onto four wheels. It had taken 5 years to reach this stage but we could at last get a feel for how the finished restoration would look. And it certainly was going to look good. The red painted components; the polished metal and chrome; the skimmed front brake discs and the zinc plated rear brake back plates; Wow! What a difference. It became clear that the finished restoration would produce a dragster more glamorous than we could ever have imagined. This could be seen even with bubble wrap remaining in place to protect some finishes. Involvement in a project like this is a fantastic privilege and totally absorbing. Pride takes second place to solving puzzles and overcoming challenges. But occasionally a point is reached in the process when the sense of achievement becomes overwhelming and for a short moment pride can be allowed its place in the sun. This was one of those moments. It can be quite emotional when bringing history back to life becomes a reality that exceeds all expectations. The February 3rd ‘Work-In’ day saw Nick Connor join our team. Nick was the first of our expaned team members (five coming forward after advertising in Eurodragster and on Facebook). He first caught the drag racing bug back in the 1970s. After building and crewing on cars for a couple of friends he built and raced a supercharged Rover V8 engined 1954 Ford Pop back in the early/mid 90`s that put down a 14.59 seconds elapsed times. This led to a Competition Altered called "Barking Mad". Its body was a much modified 1932 Model B highboy. With a 350 small block Chevy its best elapsed time was 10.23 seconds and its fastest terminal speed 132.58 mph. He raced this with the Wild Bunch from 1999 to 2003. His current car is a 1963 Trabant 601. Clearly he has a sense of humour; mandatory for becoming an ACAG crew member. A joint-owned venture with his friend Kevin Bingham, it has a full race chassis and roll cage with a Pro Street back end. Engine is 355ci small block Chevrolet. Most of the body panels have been remade in fibreglass. Welcome to the team Nick.

The main focus of the day was installing the engine along with work on the steering mechanism and water temperature sensor. The clutch throw was roughly checked at the pedal for gear change action. February 12th saw more work on the brake lines. The Pop-Off valve was installed along with the Hilborn injection unit, fuel pump and blower pipes. An oil dipstick was also modified to suit our requirements. Feb 24th saw the brake hydraulic system completed and all unions tightened ready for fluid to be added and bleeding. All gearbox levers (most freshly chromed) and foot controls were installed along with the aluminium footplate in left foot control bay. This is the only proper flooring on car and is original. The newly chromed hand brake/fuel shut-off control was installed and connected to the fuel shut-off cable (fixed to the front of the fuel pump) and the brake system. The hand brake (positioned behind the rear axle) was connected to an attachment at rear of master cylinder cross-plate and the foot brake control attached at the front. The fuel tank was installed (the steel retainers still need to be covered to reflect the original bungee straps) and all the fuel lines were connected and tightened. Nick took the firewall back to his own workshop to apply an engine turn finish both sides.